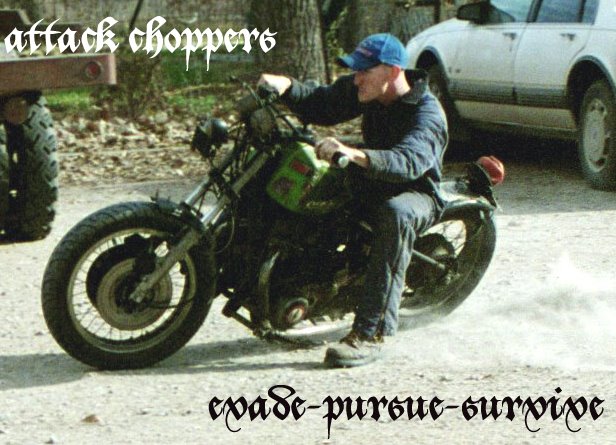

There was a time when I worked on my long bikes on a dirt floor garage that had no lights and no power... and while I wouldn't recommend it... you can do it.

Where there is a will there is a way... hand tools will go a long way with some ingenuity!

Jimmy sent in another cool update along these very lines!

(Notice he didn't skimp on the coffee mug... you gotta have SOME standards!)

Jimmy says:

"Ya know I see a lot of guys that build some amazing shit, but they have giant lathes, bridgeport mills and TIG welders that cost more than 5 house payments. I was talking to a friend earlier and he asked me how I made some of the things on my bikes, and asked if I had a lathe. I can't remember exactly what I said, but it had something to do with owning a drill, file and a $20 tap and die set from Autozone. So I got to thinking about my machining skills, or lack thereof, and I figured I would put this on here. Attached are pictures of my fantabulous fab shop. I don't have a lathe or mill, drill press, hell I don't even have a bench grinder or bandsaw. The closest thing I have is a sawsall, a drill and file (my ghetto ass lathe) and an angle grinder I put in my vice when I need a bench grinder. Did I mention Ghetto? And oh yeah, I weld everything with my POS Harbor Frieght flux core welder......."